Operational Technology

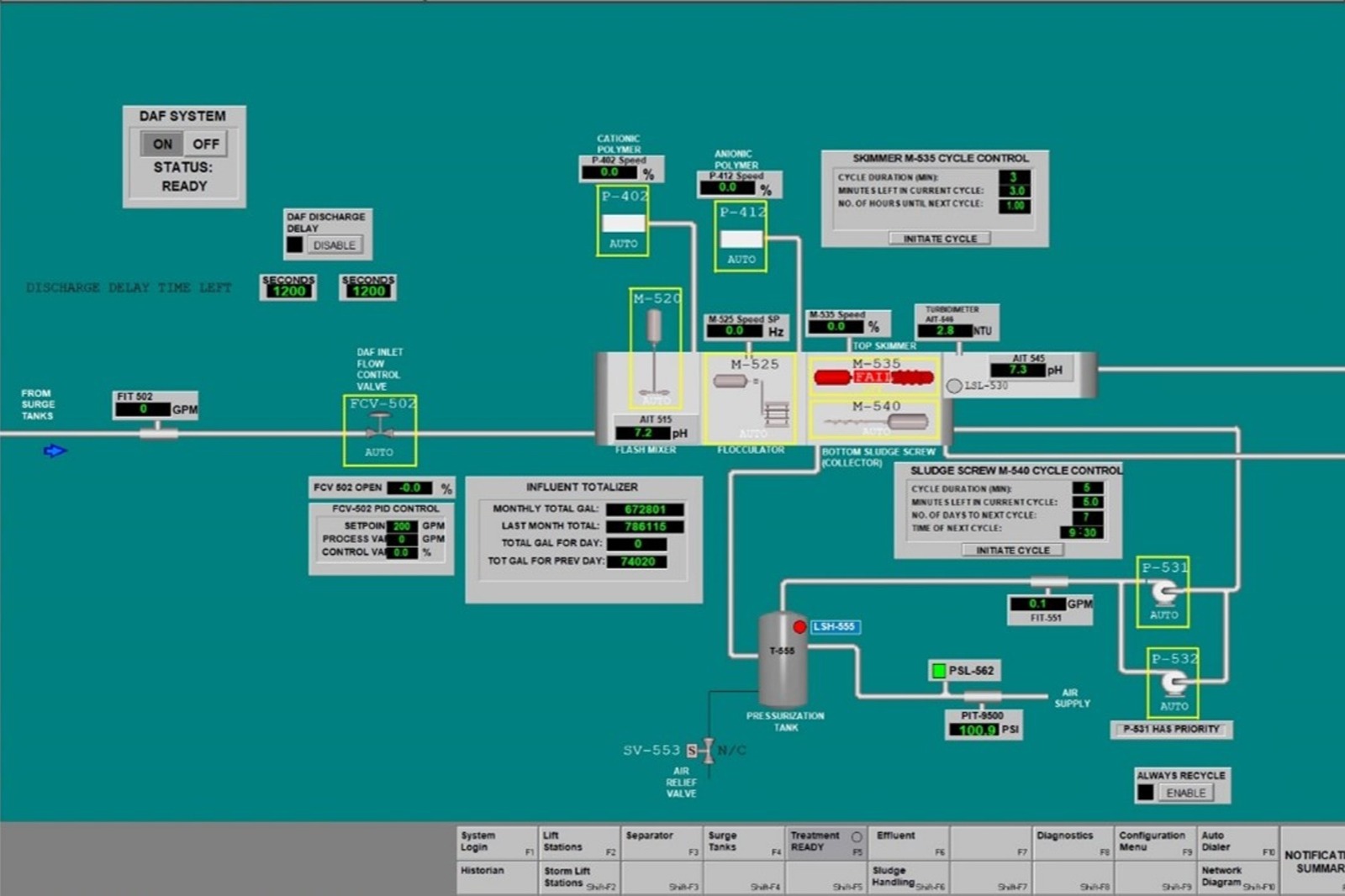

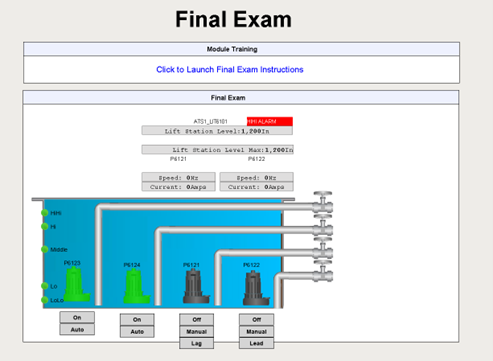

From the plant floor to mobile fleets and the cloud, Casne Engineering empowers digital transformation for real time operations. Specialized project teams of engineers and technologists provide design and implementation services for a wide range of industrial applications.

LETS DISCUSS YOUR PROJECT

Our industry principals are ready to meet and identify your needs.

Set a Meeting

Casne Engineering has a special appreciation for the technology that runs real-world operations, also known as Operational Technology (or OT). Modern operations require highly customized solutions that address a variety of unique needs, including:

-

Real-time visibility across disparate physical equipment and proprietary systems

-

Ability to detect and manage abnormal and unsafe conditions

-

Seamless integration with work management and maintenance functions

-

Ability to collect, organize, and analyze streaming sensor data

-

Reliable data exchange with expert systems and advanced analytics, such as machine learning, both on-premise and in the cloud

-

Sustainable cooperation with enterprise IT mission and priorities

-

Ability to operate, maintain, and manage without disrupting critical operations or business functions

The unrelenting pressure to accelerate production, expand operations, maintain quality, and avoid downtime presents real challenges that demand specific technology expertise and industry awareness. We believe that OT investments should deliver tangible benefits through versatile, robust, and maintainable solutions. Casne Engineering is a partner who understands the issues.

From designing and implementing off-the-shelf products and technologies to developing new and innovative solutions for unique challenges, no project is too challenging for our engineers.

DoMAIN Expertise

-

Time series databases and plant historians

-

Industrial control system (ICS) integration

-

Programmable Logic Controllers (PLC) systems

-

Manufacturing Execution Systems (MES)

-

Mobile telematics and fleet asset management

-

Industrial networks and device-level protocols

-

Embedded system design and development

-

Sensor networks and Industrial Internet of Things (IIoT)

-

Advanced alarming and notification systems

-

System visualization and real time dashboards

-

Predictive analytics and machine learning

-1-1.jpeg)